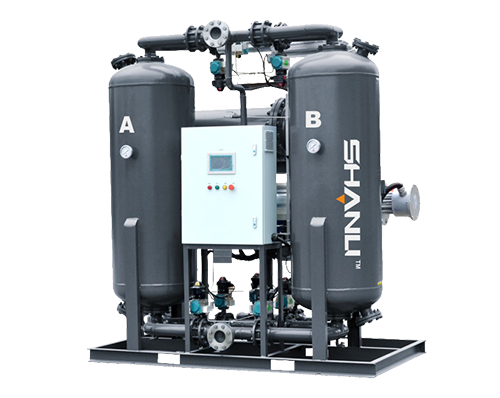

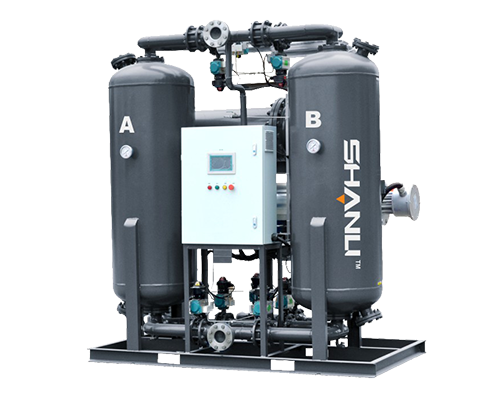

Heated Desiccant Air Dryer

Working condition and technical data

Maximum inlet air temperature:45℃

Pressure range:0.5-1.0Mpa

Pressure dew point:-20℃ ~ -40℃

Inlet oil content:≤0.1PPm

Regeneration gas consumption:≤7%

Control mode: microcomputer automatic control / PLC control

Power supply: 1-6nm 3 / min, AC 220 V / 50 Hz

AC 380 V / 220 V / 50 Hz for 8nm 3 / min and above

Period: T = 2-6 (H)

Design condition: inlet temperature: 38 ℃

Ambient temperature: 38 ℃

Working pressure: 0.7MPa

Pressure loss: ≤ 3% of design pressure

Note: other special requirements are welcome to customize.

Registration

Characteristics of micro heat regeneration adsorption dryer

- 2-6 hours standard cycle;

- The pressure dew point can reach - 20 ℃ to - 40 ℃;

- The regeneration gas consumption is less than 7%;

- High quality switching valve, stable and reliable, can ensure the integrity of the working process and prolong the working life of components;

- The activated alumina with high hygroscopicity is selected with uniform shape and size, high strength, low dew point, less dust and long service life;

- The unique regeneration pipeline design is adopted to ensure that the regeneration gas can be evenly distributed when the regeneration gas is heated and cooled, so that the adsorbent in the center of the adsorption tower is heated evenly, the heat dissipation is fast, and the regeneration is complete;

- The heater has reasonable design, good dehumidification and regeneration effect, low air consumption, high heating efficiency, and greatly reduces energy consumption;

- Programmable microcomputer controller, cycle time, adsorption, regeneration working time, heating time, heating temperature can be adjusted to achieve your satisfactory dew point value.

Product specifications

| model |

air capacity (Nm3/min) |

Heater power (kw) |

Weight of desiccant (Kg) |

Air nozzle diameter |

Net weight of equipment (Kg) |

L (mm) |

W (mm) |

H (mm) |

| SLAD-1MXF | 1.2 | 1 | 24 | G1" | 185 | 812 | 640 | 1417 |

| SLAD-2MXF | 2.5 | 1.2 | 40 | G1" | 255 | 732 | 586 | 2017 |

| SLAD-3MXF | 3.6 | 1.5 | 60 | G1" | 340 | 962 | 638 | 1711 |

| SLAD-4.5MXF | 5.0 | 2.1 | 85 | G1-1/2" | 450 | 842 | 624 | 2225 |

| SLAD-6MXF | 6.8 | 3 | 120 | G1-1/2" | 630 | 950 | 642 | 2105 |

| SLAD-8MXF | 8.5 | 4 | 158 | G2" | 680 | 1288 | 696 | 2231 |

| SLAD-10MXF | 10.9 | 5 | 190 | G2" | 810 | 1288 | 696 | 2331 |

| SLAD-12MXF | 12.8 | 5 | 190 | G2" | 810 | 1288 | 696 | 2331 |

| SLAD-15MXF | 16 | 6 | 310 | DN65 | 875 | 1310 | 771 | 2310 |

| SLAD-20MXF | 22 | 8 | 492 | DN65 | 1130 | 1410 | 775 | 2371 |

| SLAD-25MXF | 26.8 | 10 | 578 | DN80 | 1320 | 1510 | 838 | 2746 |

| SLAD-30MXF | 32 | 12 | 600 | DN80 | 1335 | 1565 | 855 | 2473 |

| SLAD-40MXF | 43.5 | 15 | 856 | DN100 | 1800 | 1854 | 983 | 2611 |

| SLAD-50MXF | 53 | 18 | 1002 | DN100 | 2010 | 1900 | 998 | 2659 |

| SLAD-60MXF | 67 | 22 | 1334 | DN125 | 2585 | 2166 | 1119 | 2803 |

| SLAD-80MXF | 90 | 27 | 1608 | DN125 | 3060 | 2864 | 1340 | 2857 |

| SLAD-100MXF | 110 | 36 | 2000 | DN150 | 4080 | 3460 | 1605 | 3048 |

| SLAD-120MXF | 130 | 42 | 2435 | DN150 | 4600 | 3560 | 1675 | 3094 |

| SLAD-150MXF | 160 | 54 | 2926 | DN200 | 5600 | 3960 | 1800 | 3332 |

| SLAD-200MXF | 210 | 72 | 4070 | DN200 | 7300 | 4360 | 2055 | 3373 |

| SLAD-250MXF | 260 | 96 | 4710 | DN250 | Detailed parameters and consultation with manufacturers | |||

| SLAD-300MXF | 310 | 120 | 6160 | DN250 | Detailed parameters and consultation with manufacturers | |||

Optional Accessories

- Pneumatic butterfly valve

- Dew point display

- Dew point energy saving control

- Special voltage

- - 70 ℃ dew point

- Adsorbent

- Not limited to this

Specializes in the manufacture and production of compressed air purification equipment.

Specializes in the manufacture and production of compressed air purification equipment.